Polyamide 6 Reinforced, abbreviated as PA6G, is a significant engineering thermoplastic material in the industry. This product is a type of polymer that stands out with its special properties and wide range of applications.

However, another important factor that maximizes the superior properties of PA6G is its semi-finished form. The semi-finished form of PA6G includes various forms designed to meet specific application requirements.

Understanding the semi-finished form of PA6G is essential to fully appreciate the role of this polyamide in the industrial field.

This form not only optimizes engineering and manufacturing processes but also becomes a determining factor in setting industry standards by providing unique solutions in various sectors.

What is PA6G?

Polyamide 6 Reinforced is a special type of polyamide 6, a rigid and durable polymer. This material stands out with its high strength, chemical resistance, and excellent friction properties. PA6G is commonly used in the industry as a replacement for metal, offering thermal and mechanical durability.

What is the Semi-Finished Form of PA6G?

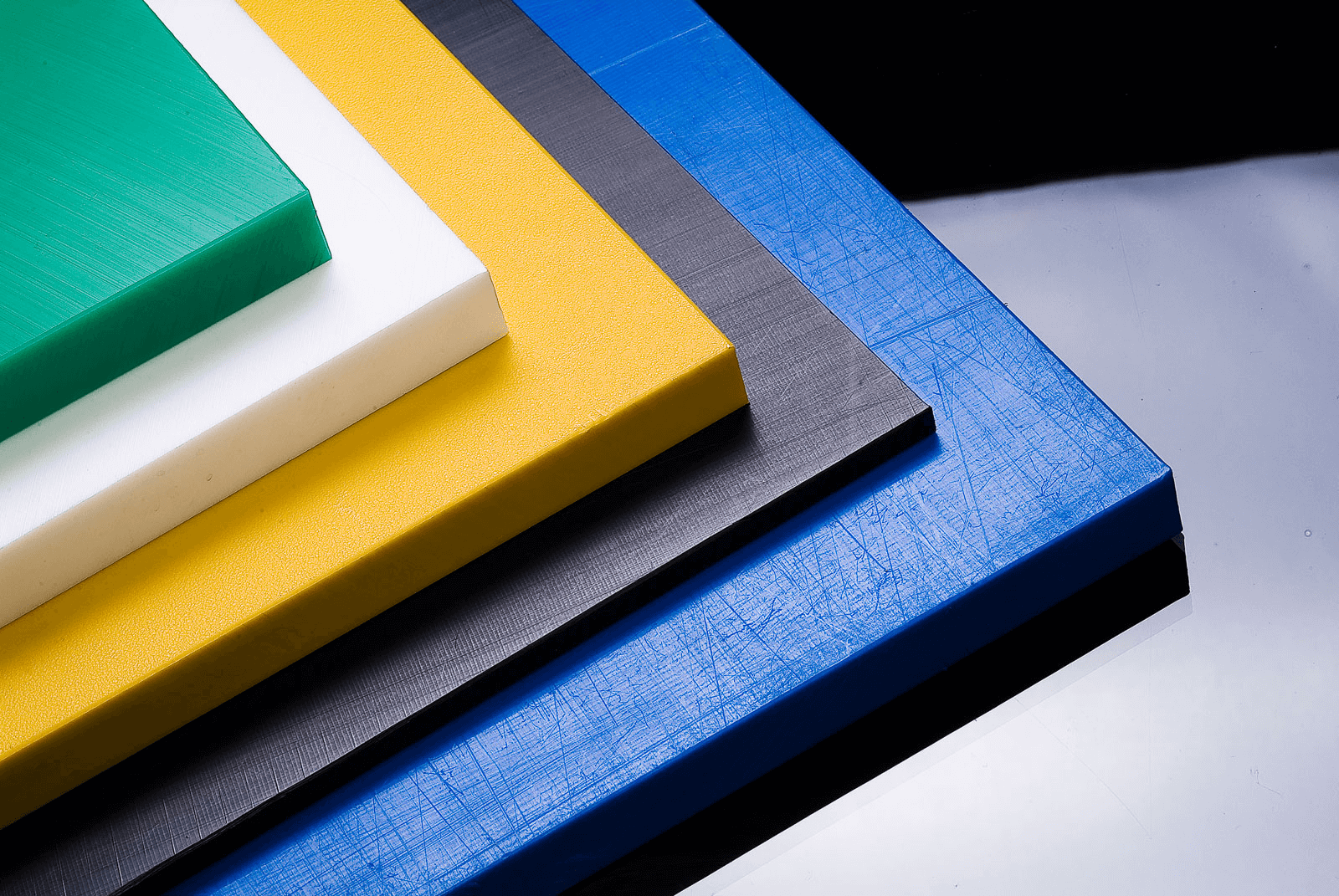

The semi-finished form of PA6G includes pre-determined forms in sizes and shapes, such as sheets, rods, pipes, and special shapes. This variety of forms allows the material to be used in various applications. The semi-finished form facilitates design and manufacturing processes by providing customized solutions to manufacturers and engineers.

What is the Role of This Form in the Industry?

The semi-finished form of PA6G is designed to provide superior performance and durability in industrial applications. Due to its durability, processability, and chemical resistance, PA6G's semi-finished form emerges as a reliable option in engineering projects, becoming an indispensable material in many critical applications across industries.

Key Features of PA6G

PA6G is a standout material among engineering thermoplastics, and its superiority lies in its key features.

Physical and Chemical Properties:

The physical properties of PA6G are decisive factors that make it indispensable in industrial applications. Its high-density structure provides excellent wear resistance and high toughness. Chemical resistance makes it ideal for use in aggressive environments. Additionally, a low friction coefficient enhances the material's sliding resistance.

Durability and Strength:

PA6G exhibits exceptional durability. Its high strength allows the material to withstand heavy loads and high stress without deformation. This feature makes PA6G particularly preferred in heavy industrial applications.

Heat Resistance:

PA6G performs excellently over a wide temperature range. High heat resistance enables the material to withstand thermal cycles and variable temperature conditions, making it a preferred choice in applications such as automotive industry components operating at high temperatures.

Comparison with Other Plastic Materials:

PA6G has several advantages compared to other plastic materials. When used as a substitute for metal, PA6G stands out with its lightweight properties while providing the durability associated with metal. Compared to other plastics, it excels in chemical resistance and thermal properties, offering a wide range of applications.

Varieties of PA6G's Semi-Finished Form

The semi-finished form of PA6G includes various specially shaped and sized forms tailored to industrial needs. This diversity enhances the material's flexible use and customizability, making it applicable in a wide range of sectors.

Sheets:

PA6G sheets are ideal for applications with large surface areas. Their high mechanical strength, durability, and processability make them suitable for large machine parts, sliders, and other applications requiring wear resistance. Additionally, their chemical resistance makes them preferred in industrial environments.

Rods:

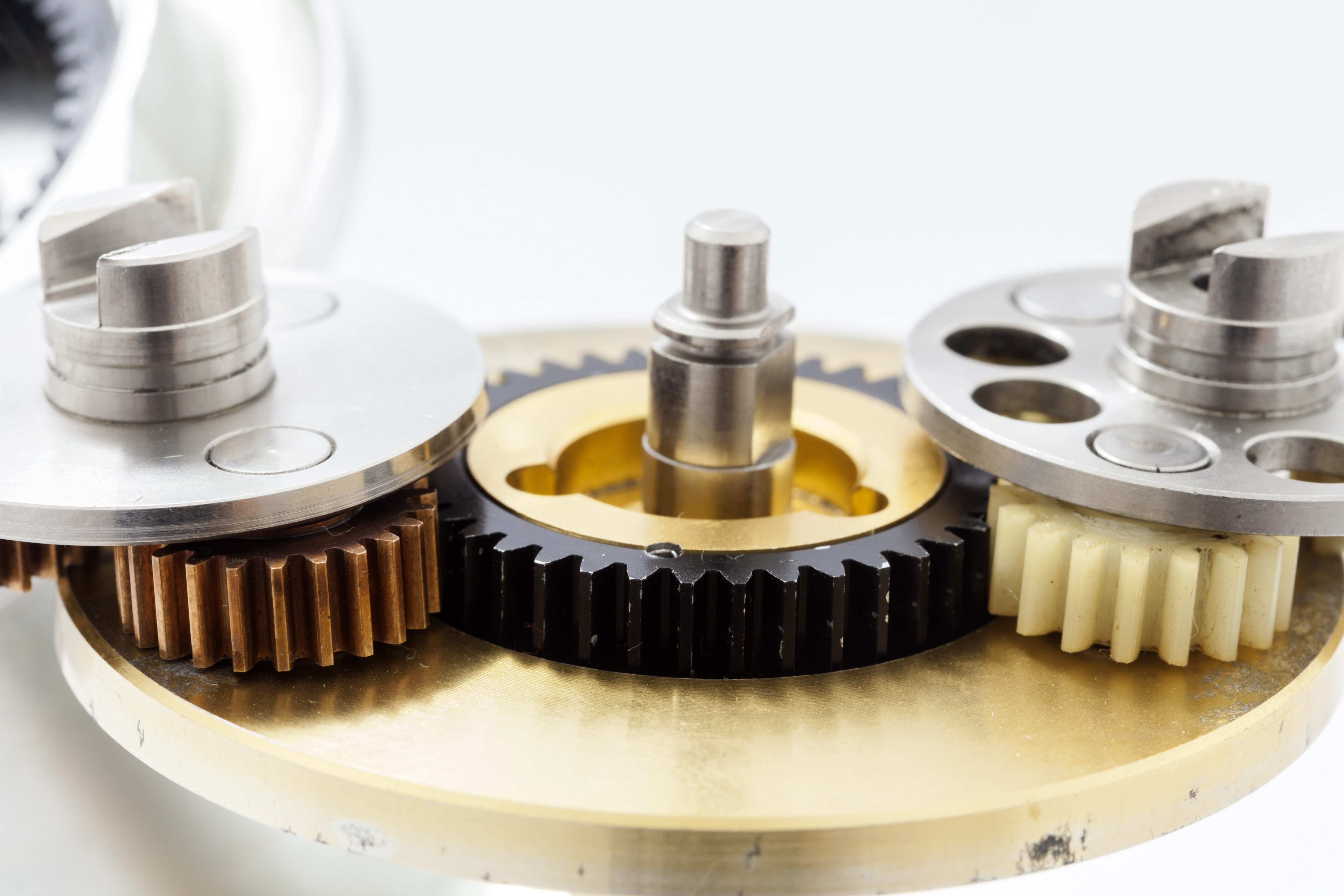

PA6G rods are typically found in round or prismatic shapes and are used in applications requiring high strength and friction resistance, such as machine parts and bearing points in machinery.

Pipes:

PA6G pipes are used in industrial applications requiring chemical resistance and durability. The lightweight and chemical resistance of pipes make PA6G a preferred option in systems transporting chemical liquids.

Special Shapes:

PA6G's semi-finished form is also offered in special shapes, providing significant advantages in the production of parts optimized for specific designs or applications. Special shapes are used to meet more specific needs in engineering projects.

Comparison with Other Semi-Finished Forms:

When compared to other plastic materials, PA6G's semi-finished form offers significant advantages. Its high strength, chemical resistance, and processability stand out among other plastics. Additionally, when used as a substitute for metal, its lightweight nature and excellent friction properties become notable.

Industrial Applications

The excellent properties of PA6G allow for various application possibilities across a wide range of industries. It provides customizable and durable solutions tailored to the unique needs of these industries.

Automotive Sector:

PA6G finds extensive use in the automotive sector, especially in components such as engine parts, gears, bearings, and other components requiring wear resistance. Its durability, lightweight, and chemical resistance make PA6G highly valued in the automotive industry.

Electrical and Electronic Industry:

In the electrical and electronic sector, PA6G is frequently used due to its high insulation properties and chemical resistance. It is an ideal material for electrical insulators, connectors, and other precision parts. Additionally, it contributes to the durability of devices in this sector.

Food and Beverage Industry:

The use of PA6G in the food and beverage industry combines compliance with hygiene standards. Its durability and chemical resistance make it particularly preferred in transportation and packaging applications. It ensures reliability in industrial kitchens and packaging processes while complying with food safety standards.

Construction Sector:

PA6G's excellent durability and strength allow for various applications in the construction sector. It is used in construction elements requiring resistance to heavy loads and wear. The material provides reliable and long-lasting solutions in construction projects.

Other Potential Applications:

The versatility of PA6G is not limited to specific industries; it extends to various potential applications. From the aviation sector to energy production, healthcare to the agricultural industry, PA6G can be used in a broad range of applications. Its adaptability potential in engineering projects continuously opens up new application areas. These industrial applications highlight the versatility and adaptability of PA6G. Engineers and industry professionals can leverage the material's properties to produce solutions for challenging application needs across various sectors.

Advantages of PA6G's Semi-Finished Form

The semi-finished form of PA6G, offering several advantages for industrial use, has gained a significant position in engineering projects and manufacturing processes. These advantages are based on various factors stemming from the material's properties.

Processability and Shapeability:

PA6G's semi-finished form demonstrates excellent performance in terms of processability. This feature allows the material to be easily cut, drilled, and shaped into various forms. Its processability enables engineers to adapt the material easily for special projects and designs. Furthermore, its capability to produce complex geometries provides industrial designers and manufacturers with a broad creative space.

Chemical Resistance:

The chemical resistance of PA6G's semi-finished form is a critical feature supporting its use in various industries. The material resists aggressive chemicals and is resistant to wear. This characteristic enhances the reliability of the material, particularly in chemical industries, food production facilities, and similar applications.

Lightweight and High Strength:

PA6G's semi-finished form stands out with its lightweight properties and high strength. This feature makes the material a preferred alternative to metal, especially in applications where a combination of lightweight and strength is essential. Industries seeking a material that is both light and strong, such as transportation, machine parts, and other applications, can benefit from PA6G.

Economic Advantages:

The economic advantages of PA6G contribute to its preference in industrial applications where cost-effective solutions are sought. The material's processability and low production costs make projects budget-friendly. Additionally, its long-lasting and durable nature reduces maintenance and replacement costs, providing economic benefits. These advantages of PA6G's semi-finished form are factors supporting its preference in a wide range of industries. Engineers and manufacturers can optimize their projects using these advantages and produce durable solutions that meet industry standards.

Processing and Application Tips

Processing PA6G's semi-finished form involves specific procedures and points to consider to bring out the material's potential and achieve excellent results.

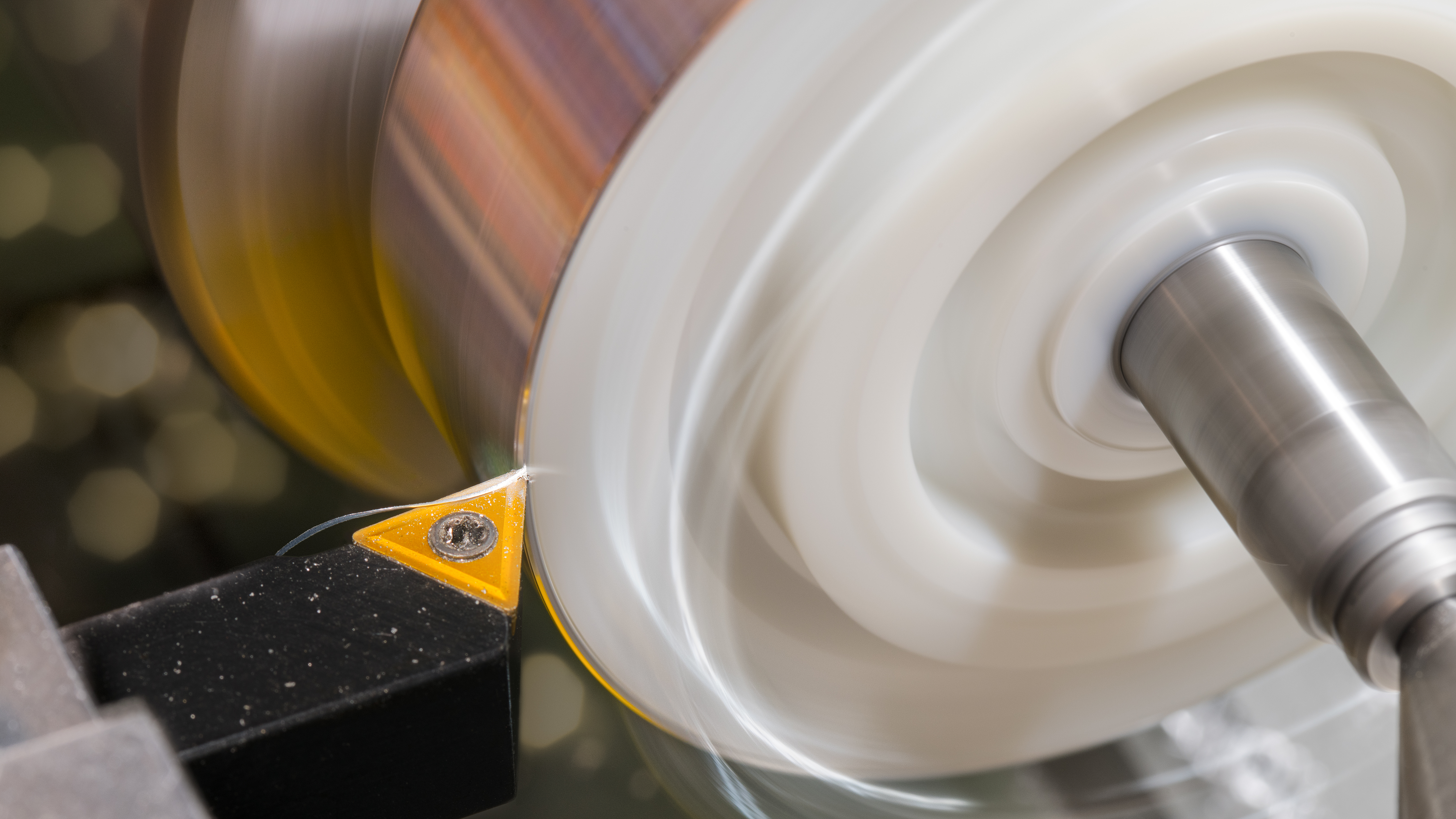

Processing Processes for PA6G's Semi-Finished Form:

Choosing the right processing processes is critical to preserving the material's properties and achieving desired results when working with PA6G's semi-finished form. Among the processing processes are milling, turning, cutting, and drilling. Care should be taken in cutting processes to prevent adverse effects on the material by paying attention to cooling methods.

Points to Consider During Application:

● Heat Control: PA6G is sensitive to thermal processes. Appropriate cooling systems should be used during processing to prevent the material from overheating.

● Cutting Speeds: Cutting speeds affect the quality of the material during processing. By paying attention to optimal cutting speeds, high-quality surfaces can be achieved.

● Tool Selection: Choosing the right cutting tools when processing PA6G's semi-finished form is crucial. Carbide cutters with high wear resistance are often preferred.

Tips for Achieving the Best Results:

● Machine Settings: Proper machine settings should be established during the processing of PA6G. This ensures the material's desired properties are maintained and provides consistency throughout the processing.

● Cooling Systems: The cooling systems used during processing can enhance the quality of the processing by preventing excessive heating of the material.

● Precise Measurements: After processing, precise measurements of the obtained parts should be taken. This is essential to verify compliance with desired tolerances and quality standards.

In conclusion, PA6G's semi-finished form, with its excellent physical and chemical properties, offers a reliable and effective material option in industrial applications. With the potential to

adapt to future developments across a wide industrial spectrum, the semi-finished form of PA6G will continue to be a crucial element for long-term success in engineering projects.