Polyethylene stands out as a prominent polymer in the modern plastic industry, being one of the pioneering materials. Equipped with exceptional flexibility and durability characteristics, this material has gained wide acceptance in the industrial field and has been extensively used in various sectors.

Designed to meet both industrial and consumer demands, polyethylene owes its popularity to its unique chemical structure.

Plastic has become an integral part of modern life, and polyethylene has played a strategic role at the forefront of this revolution.

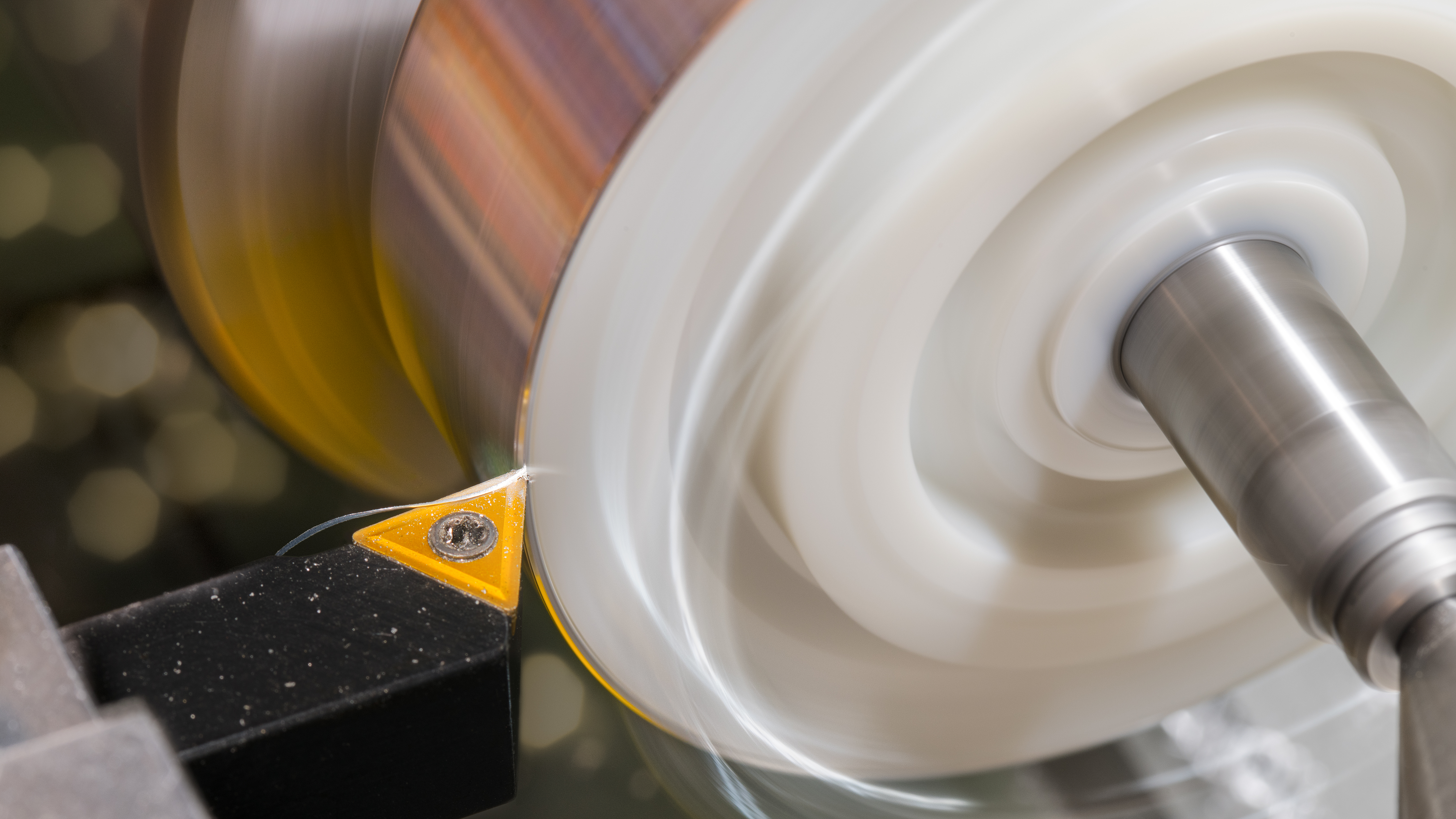

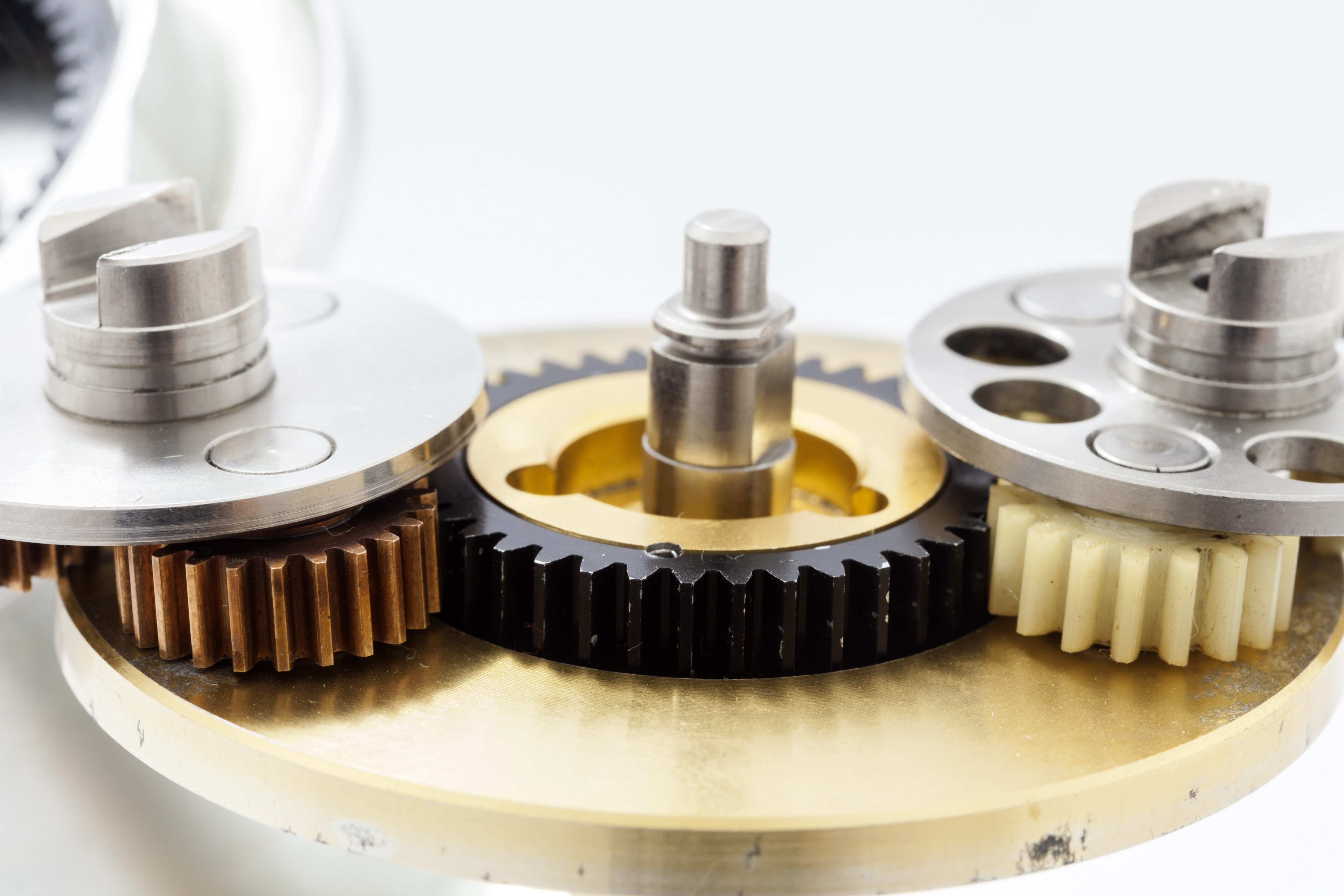

With its diverse applications ranging from the packaging industry to the construction sector, medical applications to the automotive industry, polyethylene has become an ideal choice for manufacturers and designers due to its excellent processability. Today, the unique properties of polyethylene guide efforts to increase efficiency and improve product quality in industrial processes. Not only known for its durability and flexibility, but polyethylene also stands out for its ability to be produced in various forms. This enhances its suitability for various applications in industrial design and manufacturing processes, offering innovative solutions.

What is Polyethylene?

Polyethylene is a polymer derived from ethylene, also known as polyethylene. This polymer consists of long molecular chains formed by the regular repetition of carbon and hydrogen atoms. With a chemical formula of (C2H4)n, polyethylene possesses unique physical and chemical properties due to this specific structure.

Chemical Structure and Properties:

The basic building block of polyethylene, ethylene gas, is brought together through the polymerization process. This process allows ethylene molecules to bond with each other, forming long chain-like structures. This molecular structure determines the fundamental properties of polyethylene, such as superior flexibility, durability, and chemical resistance.

The main features of polyethylene are as follows:

● Flexibility and Durability: : Polyethylene exhibits an excellent degree of flexibility while also demonstrating a high level of durability.

This feature supports the material's use in various industries.

● Chemical Resistance: Polyethylene resists acids, bases, and various chemicals, making it a preferred choice in chemical industries and laboratory applications.

● Insulation Property: Due to its electrical insulation property, polyethylene is widely used in electric cables and insulation materials.

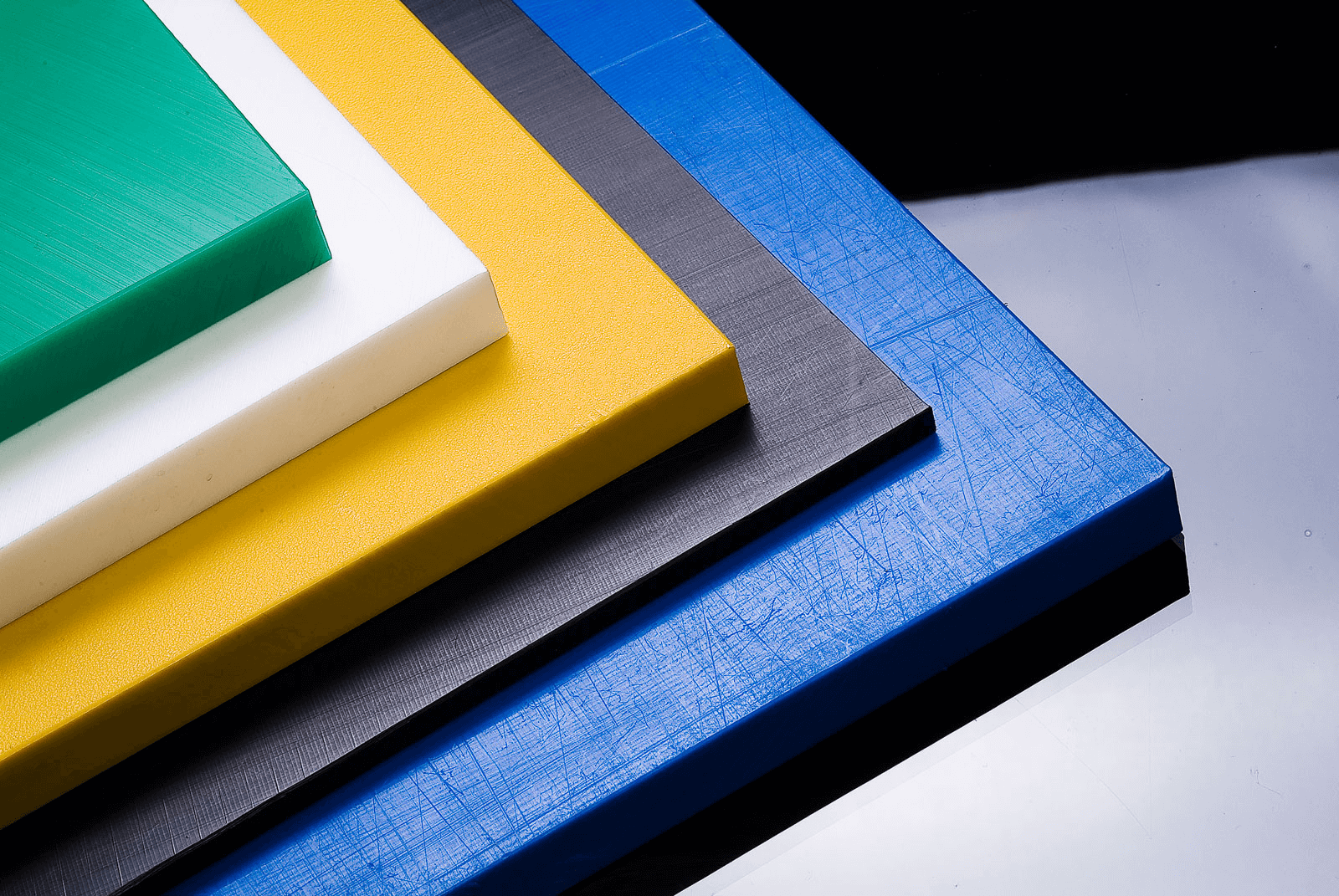

Different Types and Densities of Polyethylene:

Polyethylene can be produced in different types and densities using various manufacturing methods and additives.

This diversity enables the material to provide tailored solutions to specific needs in various industries.

Some important types of polyethylene include:

● High-Density Polyethylene (HDPE): With a high molecular weight, HDPE has a rigid and durable structure.

It is used in industrial applications such as pipe systems and water storage tanks.

● Low-Density Polyethylene (LDPE): With a lower molecular weight, LDPE has a flexible and soft structure.

It is commonly used in consumer products like packaging materials and plastic bags.

● Linear Low-Density Polyethylene (LLDPE): LLDPE is a type that enhances the properties of LDPE. It offers higher durability and tensile strength,

making it preferred in film production and the packaging sector.

The diversity of polyethylene allows for a wide range of applications in industrial settings, catering to different needs and requirements.

Applications of Polyethylene:

Thanks to its superior properties, polyethylene has found extensive use in various industries, playing a significant role in these fields.

Packaging Industry:

Polyethylene is considered an essential material in the packaging industry. Its use in products such as food packaging, plastic bags, and film materials provides an effective solution for preserving and transporting food products, owing to the material's flexibility and barrier properties. The lightweight and durable nature of packaging materials also make them preferable in the consumer products industry.

Construction Sector:

The durability of polyethylene allows its use in various applications in the construction sector. Its widespread use in products such as pipe systems, water storage tanks, insulation materials, and construction panels is due to the material's long-lasting and resilient structure.

Medical and Health:

In the medical and health field, polyethylene is widely used in various applications due to its sterilization properties and biocompatible nature. Products such as medical equipment, surgical materials, prosthetics, and implants highlight the material's suitability for diverse healthcare needs.

Automotive Industry:

The lightweight and durable characteristics of polyethylene make it widely used in the automotive industry. In applications like vehicle parts, interior trims, fuel tanks, and coating materials, polyethylene is preferred to enhance overall performance and ensure fuel efficiency.

Environmental Impacts of Polyethylene:

Polyethylene, with its extensive usage and durability, also draws attention due to its environmental impacts.

Recycling Opportunities and Environmental Impacts of Polyethylene:

Polyethylene stands out as a more sustainable option due to its compatibility with recycling processes. Recycling opportunities allow polyethylene to play an effective role in waste management. However, while some types of polyethylene yield better results in recycling processes, others may present challenges. This variation depends on the type of material and production processes. The environmental impacts of polyethylene include waste management, plastic pollution, and adverse effects on natural ecosystems. Therefore, continuous efforts are necessary for waste reduction, recycling, and minimizing environmental impacts to ensure the sustainable use of polyethylene.

Sustainable Plastic Production and the Role of Polyethylene:

The plastic industry is revisiting plastic production processes and turning towards green technologies to achieve sustainability goals. In this context, the production of polyethylene takes a central place in sustainability efforts. Factors such as the use of renewable energy, reduced carbon footprint, and design approaches that extend the material's lifespan contribute to strengthening the role of polyethylene in sustainable plastic production. Moreover, diversifications such as biodegradable polyethylene are being explored, aiming for alternatives that break down more quickly in nature and cause less harm to the environment. This is a significant step towards steering the future role of polyethylene in the plastic industry in a more environmentally sustainable direction. Research and industry efforts in managing the environmental impacts of polyethylene and playing a role in a sustainable future are contributing to reducing the environmental effects of plastic materials.

The Future of Polyethylene Technology:

While continuing to be a cornerstone of the plastic industry, polyethylene is witnessing significant steps towards potential developments and environmentally friendly alternatives in the future.

Innovative Polyethylene Technologies and Potential Future Developments:

Future polyethylene technologies aim to further enhance the material's physical and chemical properties. Nanotechnology is an innovative approach with the potential to optimize the mechanical properties of the material. With nanotechnology, the durability, flexibility, and lightweight nature of polyethylene can be further improved, making the material more versatile for various industries. Additionally, research into environmentally friendly alternatives such as biodegradable polyethylene and recyclable polymers strengthens efforts to reduce the environmental impacts of the material. The use of these alternatives can alleviate concerns about waste management and plastic pollution, making polyethylene's future role more sustainable.

Environmentally Friendly Alternatives and the Future of Polyethylene in Sustainability:

Research on various environmentally friendly alternatives is rapidly progressing to shape a sustainable future for polyethylene. Bioplastics, produced from renewable sources and capable of natural decomposition, are among these alternatives. These materials have significant potential to reduce the environmental impacts of polyethylene and decrease dependence on natural resources. Furthermore, sustainability-focused production processes and the use of green energy aim to increase environmentally friendly practices in polyethylene production. These steps represent industry-wide efforts to minimize the environmental impacts originating from the production of the material. In conclusion, the significance of polyethylene in the plastic industry is strongly emphasized by its extensive use in various sectors and its durability. However, as awareness of the environmental impacts of the material increases, ongoing research and industry efforts towards potential developments and environmentally friendly alternatives will contribute to the evolution of polyethylene as a sustainable material. This will reflect the industry's response to future demands and environmental responsibilities.