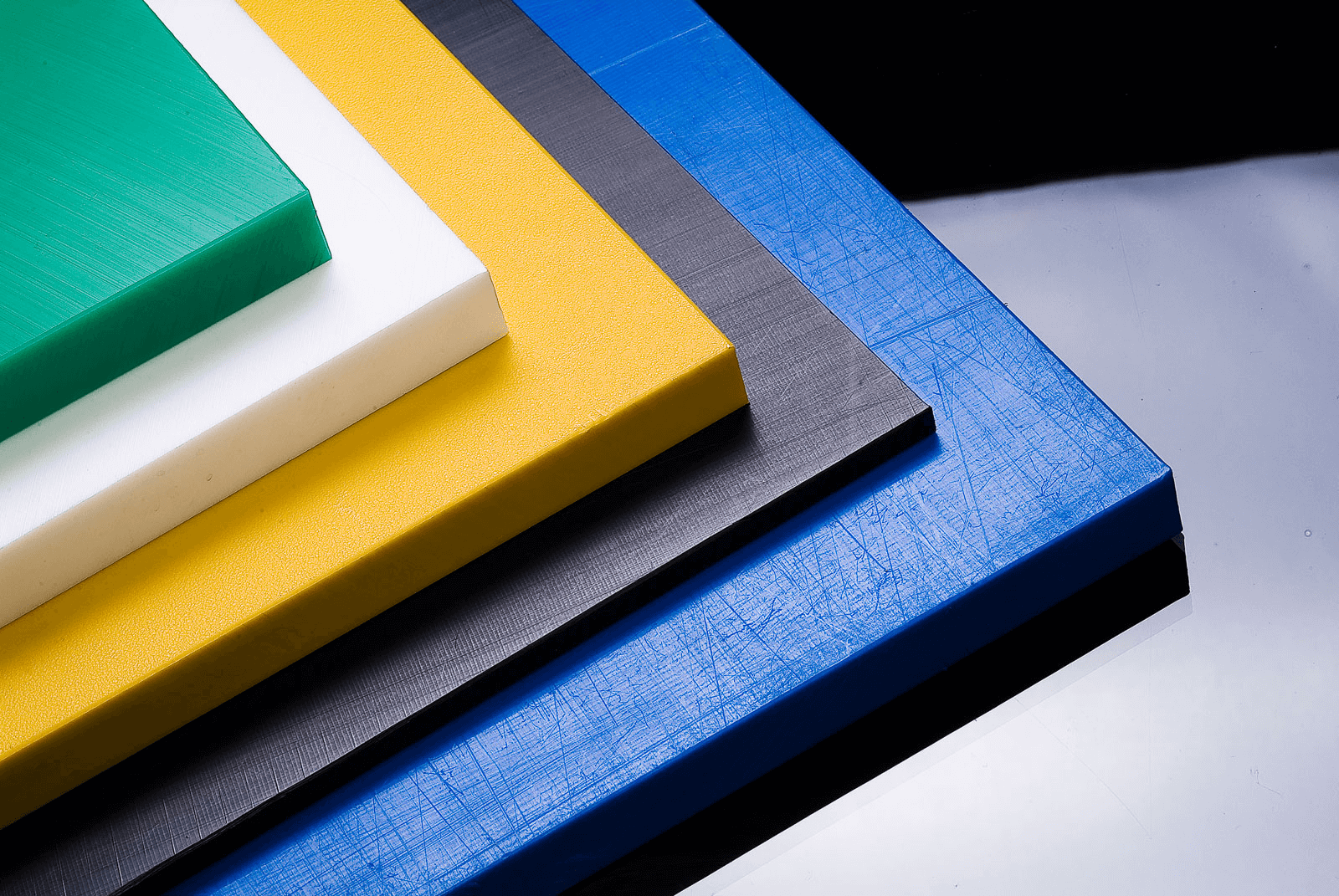

Polyamide, as an indispensable part of contemporary industry, stands out as a polymer with excellent durability and strength. This unique material plays a critical role in complex industrial processes due to its chemical structure, which consists of long-chain molecules forming a network.

This specific structure provides exceptional resistance and flexibility to polyamide.

In the industrial world, the various properties of this material encourage its use across different sectors.

Industrial Diversity of Polyamide:

Polyamide finds applications in a wide range of industries, from the textile sector to the automotive industry, packaging to the medical field. In the textile sector, it plays a significant role in the production of durable products like nylon fabrics and stockings. In the automotive industry, it is widely used in critical components such as engine parts and brake hoses.

Advantages Provided by Polyamide:

Among the advantages offered by this polymer, high strength, durability, chemical resistance, and lightweight stand out. In industrial applications, the combination of these properties makes polyamide the material of choice. Its durability, longevity, and suitability for various conditions are particularly appreciated by industry leaders.

Polyamide and Technological Advancements:

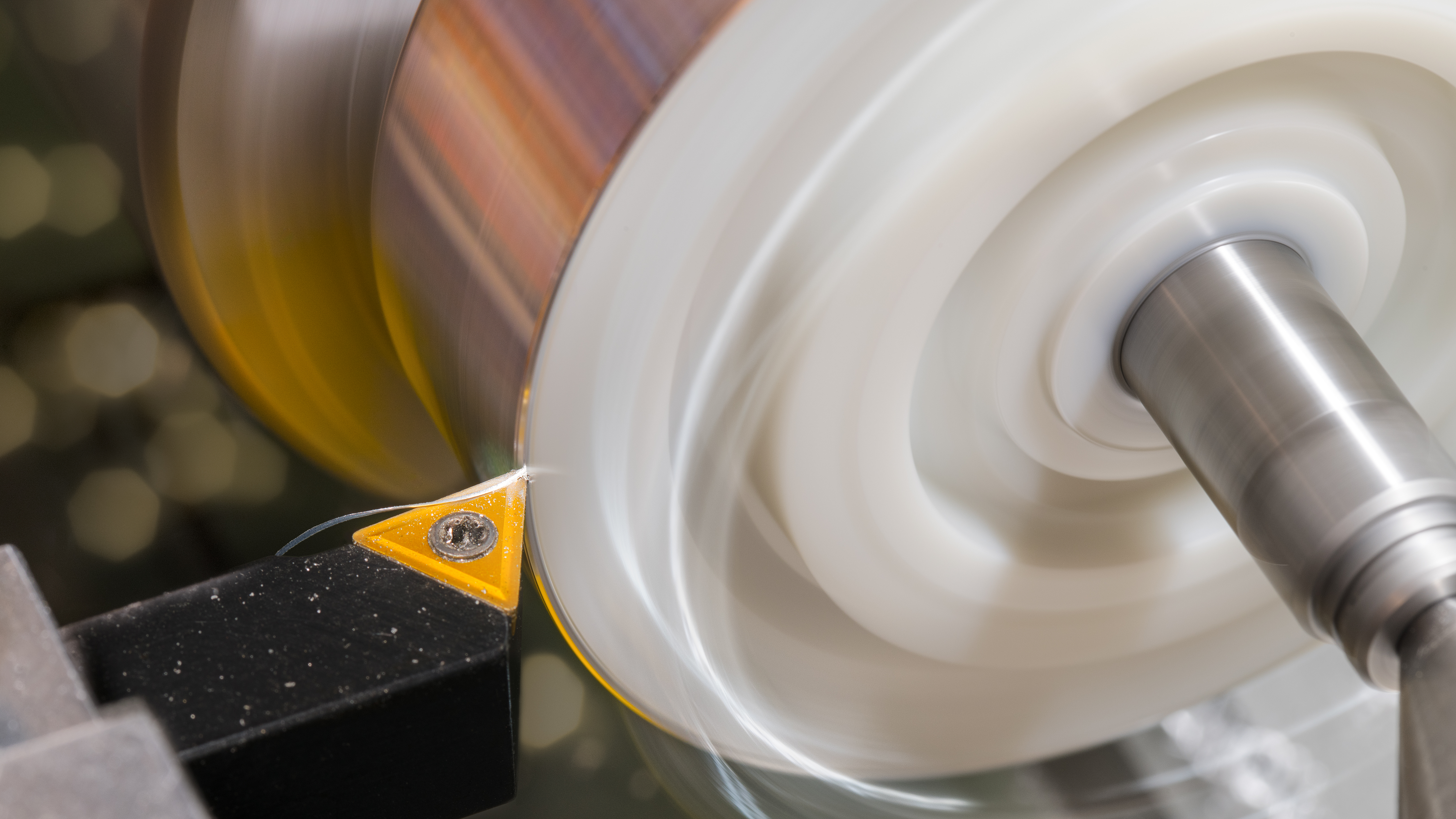

Rapid technological progress has further optimized the use of polyamide. New manufacturing methods and improved formulations have enhanced the performance of this material, making its integration into industrial processes more effective. This ensures that polyamide plays a pioneering role in future industrial developments.

Chemical Intellectual Structure of Polyamide:

Polyamide is an elite member of the synthetic polymer family and is commonly known as nylon. The material manifests itself with complexity and excellent organization in its chemical structure. The fundamental feature of polyamide is the carefully arranged network of incredibly long-chain molecules with strong bonds. This unique molecular structure provides polyamide with exceptional durability and strength. The specific configuration on the molecular plane determines the material's physical properties, giving it resistance, elasticity, and thermal stability. Thanks to this striking molecular arrangement, polyamide has become a phenomenon not only among synthetic polymers but also in general material science.

Intricacies of Chemical Bonds in Polyamide:

The durability of polyamide stems from the special nature of its chemical bonds. These bonds create a structure where molecular chains are tightly interconnected, imparting strength to the material. Consequently, polyamide becomes a preferred material in various industries that prioritize durability and performance. The chemical intellectual structure of polyamide not only determines its physical properties but also defines its suitability for various applications. This adaptability is appreciated by many sectors in the industrial world that focus on durability and performance. Thus, the chemical structure of polyamide, by highlighting the material's unique properties and industrial value, emphasizes that this synthetic polymer is not just a material but also a scientific masterpiece.

Exceptional Physical and Chemical Properties of Polyamide:

1. High Strength and Durability:

Perhaps one of the most notable features of polyamide is its exceptional high strength and durability. The material can carry heavy loads due to its strong molecular bonds, playing a critical role in the production of durable and long-lasting products in industrial applications.

2. Flexibility and Elasticity:

Polyamide offers a remarkable balance of flexibility and elasticity. The molecular structure provides the material with the flexibility to bend and stretch, making it suitable for a wide range of applications from the textile industry to the automotive sector.

3. Chemical Resistance:

Polyamide is a polymer with chemical resistance. Its resistance to chemical substances allows the material to be used in various industries under different conditions. This feature helps maintain the durability and performance of polyamide.

4. Heat Resistance:

Polyamide exhibits resistance to high temperatures. This characteristic enables the material to be safely used in automotive engines and industrial equipment. The heat resistance of polyamide ensures stable performance over a wide temperature range.

5. Lightweight:

Polyamide stands out for its lightweight structure. Particularly in industries such as automotive and aerospace, where lightweight yet strong materials are in demand, polyamide is preferred. These exceptional physical and chemical properties enable polyamide to have a wide range of applications across various industries. These features, based on high-performance standards, make polyamide a key player in the industrial world.

Impressive Application Areas of Polyamide in Various Sectors:

1. Textile Industry: Nylon Fabrics, Stockings, and Underwear:

Polyamide plays a key role in the production of innovative and durable fabrics in the textile industry. Nylon fabrics, with a combination of durability and flexibility, are particularly notable. Additionally, the lightweight and comfort provided by polyamide-based underwear and stockings make them preferred choices.

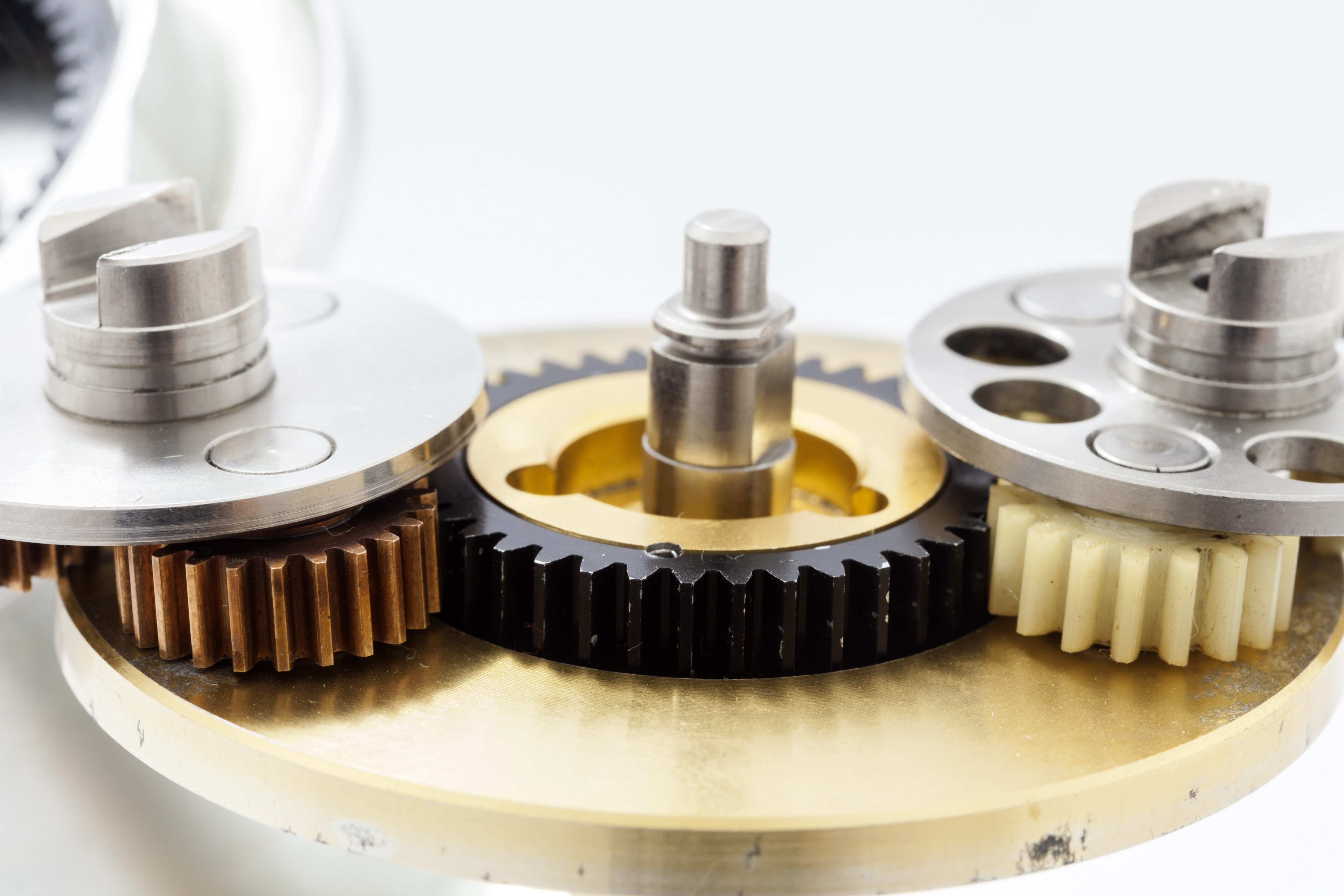

2. Automotive Industry: Engine Parts, Brake Hoses:

Polyamide is widely used in the production of various components in the automotive industry. Engine parts benefit from the high strength and heat resistance of polyamide, while brake hoses stand out for their flexibility and chemical resistance. This makes polyamide a crucial material for the production of reliable and durable automotive parts.

3. Packaging Industry: Durable Packaging Materials:

Polyamide is utilized in the packaging industry to produce robust and durable materials. Especially, durable packaging products used for transporting and storing various materials highlight the strength and lightweight nature of polyamide.

4. Electronic Industry: Cable Insulations:

Polyamide is commonly used in cable insulations in the electronic industry. Its ability to provide electrical insulation, chemical resistance, and durability make polyamide essential in ensuring the safe and effective operation of electronic devices.

5. Medical Industry: Medical Devices and Implant Materials:

Polyamide finds applications in the medical industry for the production of surgical implant materials and medical devices. Its biocompatible properties play a significant role in designing materials compatible with the human body. Polyamide is a reliable and durable option for various applications in the medical field.

Polyamide and Sustainable Waste Management:

Polyamide stands out as an environmentally friendly option due to its recycling capabilities. This unique feature not only positions polyamide as a material for industrial applications but also as a cornerstone of a sustainable future. The recycling capabilities of polyamide allow the material to be reprocessed after use, leading to the production of new products. This minimizes waste, reduces environmental impact, and contributes to more efficient use of natural resources. This eco-friendly approach enhances the sustainability of the industry by minimizing waste generated from polyamide production. Simultaneously, it provides a significant advantage in offering environmentally conscious products to consumers. Polyamide's sustainable waste management features enable the industry and consumers to fulfill their environmental responsibilities. This direction supports the material's future use while guiding towards the adoption of goals to minimize environmental impact.

Polyamide and Progressive Technological Evolution:

The rapid evolution of technology has brought about significant changes in the use of polyamide. This polymer leads advancements in material engineering by increasing its use across industries through new manufacturing methods and enhanced features. The technological adaptation of polyamide has allowed it to surpass the limitations of previous generations of materials. Innovative production methods enable the acquisition of more complex and customizable forms of polyamide. This facilitates more effective use of the material across diverse industrial applications. Advanced features have further enhanced the durability, flexibility, and thermal stability of polyamide. This has paved the way for the material to find a broader range of applications, particularly in the automotive, aerospace, and medical sectors. For example, new generations of polyamide may possess higher heat resistance or specific chemical properties, providing more options for industries. The technological evolution of polyamide ensures that the material is recognized not only for its durability and strength but also for its innovative and sustainable features. This positions the material to continue adapting to future technological developments and meeting industrial demands. With technological advancements, polyamide will remain a significant figure in material engineering in the coming years. In summary, polyamide holds a crucial position in the industrial field due to its superior properties and versatile potential uses. Its durability and strength make it an ideal choice in various sectors, and its environmentally friendly features shine as sustainable material options. This impressive polymer is used across a spectrum of industries, from the textile sector to the automotive industry. Known for its strength, polyamide provides reliable and long-lasting solutions in industrial applications. With technological advancements, an inevitable increase in the use of polyamide is expected. New manufacturing methods and features allow the material to find a place in more industries, while sustainable waste management features provide an environmentally conscious option. In conclusion, polyamide is a material that has a strong impact on the industrial world and is likely to gain further prominence in the future. Its success in various application areas strengthens its indispensable role in material engineering, continuing to meet industrial demands.